Technology

Research & Development

At our Research and Development facility, we tackle new challenges with innovative tech. Our solutions meet global standards for our customers.

Reliable, affordable, low-carbon and secure electric power will enable nations to continue economic growth, improve public health and safety, and reduce GHG emissions. However, we will require more power as the world shifts to renewable and clean alternatives such as electric heating, electric vehicles, and greener industrial processes. Our power-hungry society will need reliable and energy-efficient grids. Globally, transmission energy losses are about 8% of total power transmitted, equating to over 13,000 TWh. Reducing these losses by even 0.1% with better insulator technology could result in emission reductions of over 4 million tonnes of CO2e, equivalent to the CO2e emissions from 450 million gallons of gasoline1. Our innovative electrical insulator product delivers multiple benefits over traditional insulators. The ASAsoft™ 2.0 insulator components have lower emissions, a longer lifespan, and improved handling safety.

Our Research and Development center is equipped with advanced facilities for developing high-performance polymer compounds based on synthetic elastomers, plastics, polymer blends, alloys, and composites. We carry a full range of facilities for testing the following:

- Mechanical Properties

- Electrical Properties

- Weather & Ageing Resistance

- Fire Resistance Properties

- Hydrophobicity of Polymer Compounds

With the growing interest in composite insulators, we aim to develop technology to manufacture advanced materials for high-performance applications using Nanotechnology and polymer composite Science.

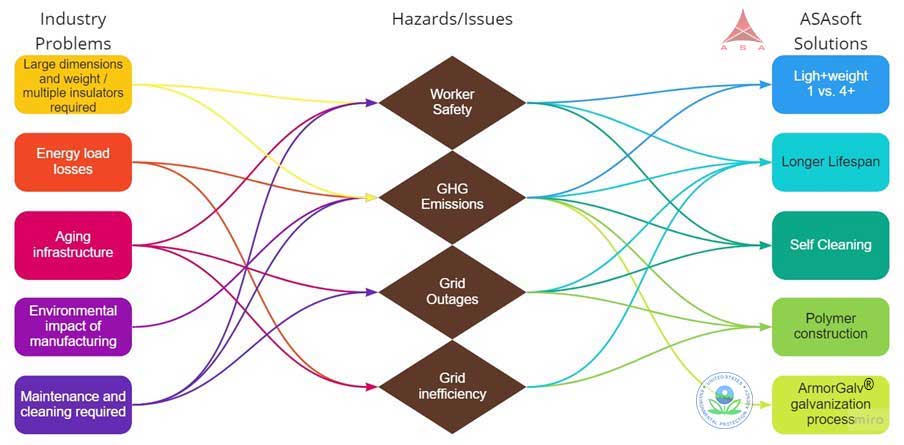

| Industry Problems | ASAsoft™ Solutions |

| Large Dimensions and Weight/Multiple Insulators Required | – Lightweight – fewer workers are needed to install the insulator, reducing the number of workers exposed to the hazards of working off the ground on high-power T&D lines. – A standard ASAsoft™ 35kV insulator replaces up to four ceramic insulators, reducing GHG emissions of materials required |

| Energy Load Losses | – Polymer Construction – will not crack: this reduces energy load losses and also eliminates the possibility of radio frequency interference, which is common with fractured porcelain insulators. – Globally, transmission energy losses are about 8% of total power transmitted, equating to ~13867 TWh. Reducing these losses by 0.1% (estimated contribution of damaged insulators) could result in emission reductions of over 4 million tCO2e. |

| Aging Infrastructure | – Longer Lifespan (predictable 20-25 years – Insulators do not need to be replaced as frequently. |

| Environmental Impact of Manufacturing | – ArmorGalv® Galvanization Process (thermal diffusion galvanizing) produces 99% less wastewater and 99% less solid waste than standard hot-dip galvanizing. |

| Maintenance and Cleaning Required | – Self-Cleaning/hydrophobic materials– traditional T&D Insulators need to be cleaned frequently, often by workers flown in by helicopter – see this video – any mistakes with matching voltage potential could be fatal for multiple individuals. – Reduced cleaning equates to reduced maintenance costs, less use of fossil fuel-powered vehicles & equipment, and most importantly reduced hazard exposure. |